Metal Framing & Deck Manufacturers

BUILDING MATERIALS

☎ 732 667 3636

Submittals

- Home

-

Steel Framing Products

Products{{ main_menu.data.list_1_title }} {{ main_menu.data.list_1_title }}{{ main_menu.data.list_2_title }} {{ main_menu.data.list_2_title }}

- Big Apple Joists

- Decking

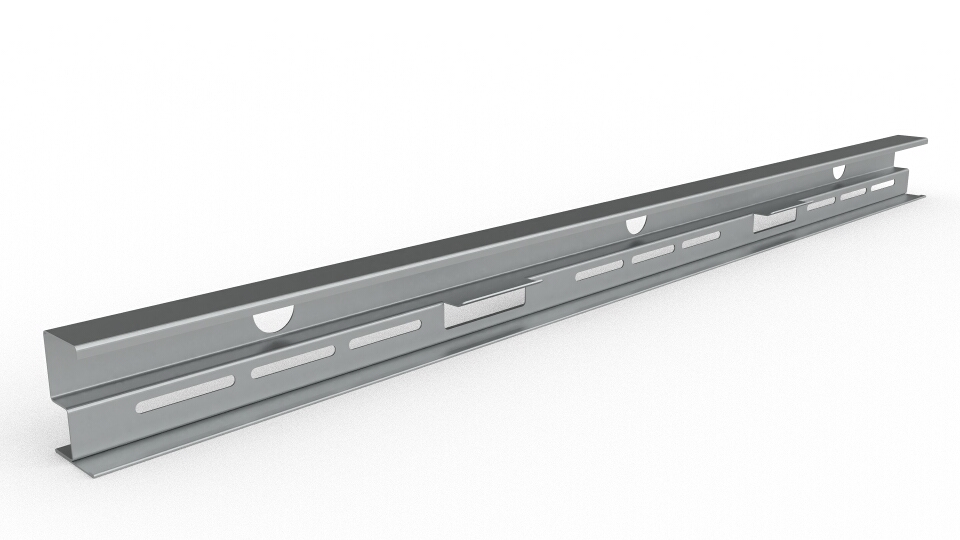

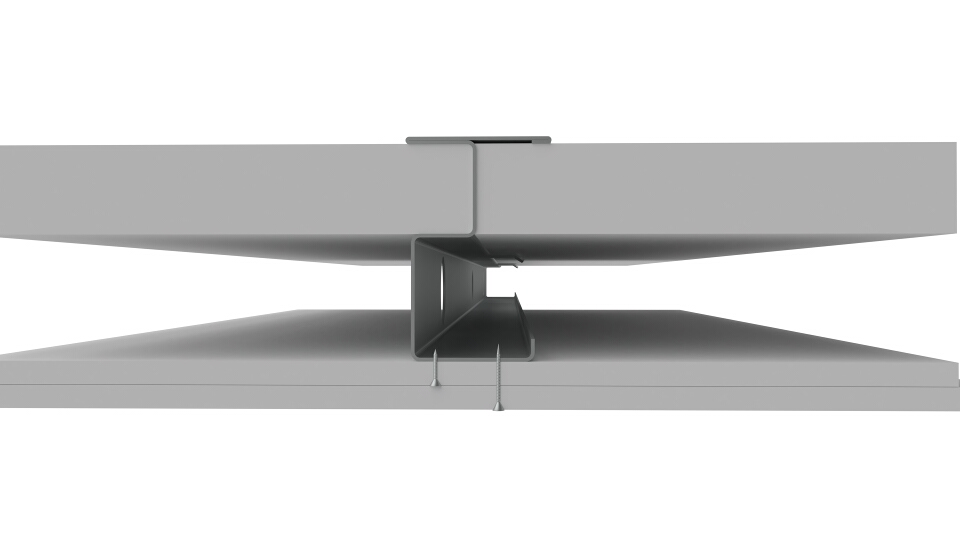

- Strut Channel

- Resources

- Submittals

- About

- Contact